| Min. Order: | 100 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF,FCA,EXW |

| Payment Terms: | T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

| Means of Transport: | Ocean, Land |

| Production Capacity: | 20000 pcs/month |

| Packing: | Neutral Carton... |

| Delivery Date: | 30 days | Brand Name: | HOLK |

|---|---|---|---|

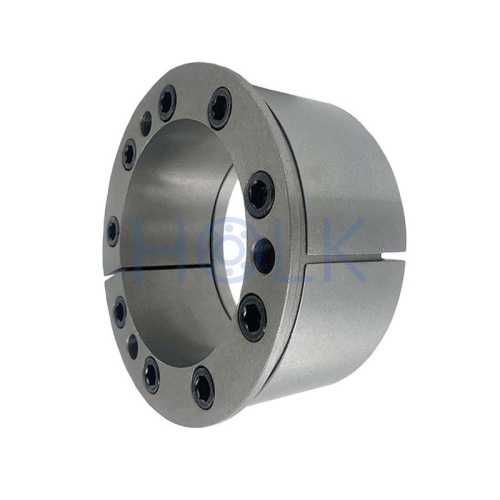

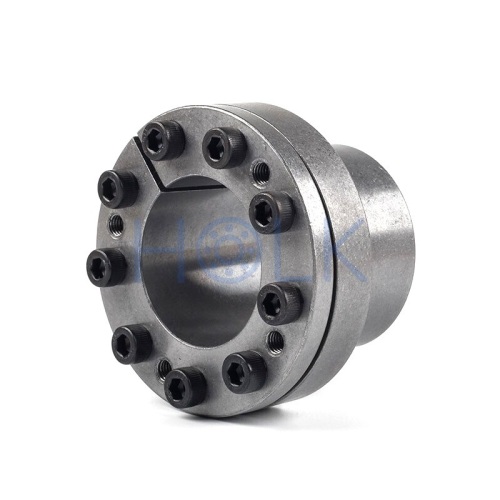

| Product Name: | Shaft Locking Assemblies, Keyless Shaft Power Lock, Shaft Clamping Elements, Locking Device | Series: | Z9 Series |

| Inner Diameter d: | 100mm - 420mm | Outer Diameter D: | 145mm - 515mm |

| Structure: | Outer Ring, Inner Ring, Clamping Screws | Torque Range: | 9.6 KN.m - 410 KN.m |

| Material: | #45 Steel | Features: | Long life service |

| Packaging: | Neutral Carton/Plywood Box |

Shaft Clamping Elements, also known as Keyless Power Locking Assemblies, by means of frictional forces, provide connection of all types of transmission equipment to their respective shafts, enabling transmission of both torque and axial thrust loads. Precision tapered thrust cones within the clamping elements create high pressure between shaft and hub to securely fasten pulleys, sprockets, gears, impellers, propellers etc.

These keyless lock assemblies are shaft-to-hub frictional locking devices that provide easily adjustable and releasable mechanical shrink fit. They offer simple installation, increased shaft strength and high torque transmission capacity.

HOLK Bearing offers a comprehensive range of different types of clamping elements to meet individual needs.

Product Name: Shaft Locking Assemblies, Keyless Shaft Power Lock, Shaft Clamping Elements, Shaft Locking Device, Cone Clamping Elements, Shaft Couplings

Series: Z9

Material: #45 Steel

Construct: Inner Ring, Outer Ring, Locking Screws/Bolts

Screws/Bolts Property Class: Class 12.9

Drawing and Technical Parameters of Z9 series Shaft Locking Assemblies-Shaft Clamping Elements

| Z9 Series Locking Assemblies - Shaft Clamping Elements - Shaft Power Lock - Cone Clamping Elements | |||||||||||||

| Dimension | Screw | Rated Load | Pressure on shaft | Pressure on hub | Screw Tightening Torque | Weight | |||||||

| d | D | L1 | L | e | B | d1 | n | Axial Force | Torque | Pf | Pf′ | MA | |

| F1 | M1 | N/mm2 | N/mm2 | N·m | kg | ||||||||

| mm | KN | KN·m | |||||||||||

| 100 | 145 | 54 | 75 | 5 | 65 | M12×60 | 8 | 192 | 9.6 | 102 | 70 | 145 | 4.7 |

| 110 | 155 | 54 | 75 | 5 | 65 | M12×60 | 8 | 191 | 10.5 | 93 | 66 | 145 | 5.1 |

| 120 | 165 | 54 | 75 | 5 | 65 | M12×60 | 9 | 216 | 13 | 96 | 70 | 145 | 5.5 |

| 130 | 180 | 63 | 84 | 6 | 72 | M12×70 | 12 | 287 | 17.8 | 100 | 78 | 145 | 7.5 |

| 140 | 190 | 63 | 84 | 6 | 72 | M12×70 | 12 | 287 | 20.2 | 94 | 69 | 145 | 7.9 |

| 150 | 200 | 63 | 84 | 6 | 72 | M12×70 | 12 | 287 | 21.6 | 88 | 66 | 145 | 8.4 |

| 160 | 210 | 63 | 84 | 6 | 72 | M12×70 | 15 | 360 | 28.8 | 101 | 77 | 145 | 8.9 |

| 170 | 225 | 63 | 84 | 6 | 72 | M12×70 | 16 | 383 | 32.6 | 101 | 76 | 145 | 10.5 |

| 180 | 235 | 63 | 84 | 6 | 72 | M12×70 | 18 | 431 | 38.8 | 108 | 82 | 145 | 11 |

| 190 | 250 | 69 | 94 | 6 | 81 | M14×75 | 15 | 493 | 46.8 | 106 | 80 | 230 | 14.3 |

| 200 | 260 | 69 | 94 | 6 | 81 | M14×75 | 16 | 526 | 52.8 | 100 | 77 | 230 | 15 |

| 220 | 285 | 69 | 94 | 6 | 81 | M16×75 | 14 | 640 | 70 | 119 | 92 | 355 | 17.8 |

| 240 | 305 | 86 | 112 | 7 | 98 | M16×90 | 16 | 731 | 88 | 96 | 75 | 355 | 23.2 |

| 260 | 325 | 86 | 112 | 7 | 98 | M16×90 | 18 | 822 | 107 | 103 | 82 | 355 | 24.8 |

| 280 | 355 | 94 | 120 | 8 | 106 | M16×100 | 20 | 910 | 128 | 96 | 75 | 355 | 33 |

| 300 | 375 | 94 | 120 | 8 | 106 | M16×100 | 22 | 1000 | 151 | 99 | 79 | 355 | 36 |

| 320 | 405 | 109 | 142 | 8 | 125 | M20×120 | 18 | 1280 | 206 | 101 | 80 | 690 | 52 |

| 340 | 425 | 109 | 142 | 8 | 125 | M20×120 | 20 | 1420 | 242 | 106 | 85 | 690 | 54 |

| 360 | 455 | 120 | 159 | 8 | 140 | M22×130 | 20 | 1770 | 319 | 113 | 89 | 930 | 72 |

| 380 | 475 | 120 | 159 | 8 | 140 | M22×130 | 20 | 1770 | 337 | 109 | 87 | 930 | 75 |

| 400 | 485 | 120 | 159 | 8 | 140 | M22×130 | 20 | 1770 | 355 | 101 | 83 | 930 | 79 |

| 420 | 515 | 120 | 159 | 8 | 140 | M22×130 | 22 | 1980 | 410 | 107 | 87 | 930 | 82 |

Great care has been taken to ensure the correctness of the information contained in this publication but no liability can be assumed for any incorrect or incomplete data. Our technical department reserves the right to final interpretation.

When ordering, please advise the d x D (ID x OD, e.g. 300x375) and series (e.g. Z9).

Our Locking Assemblies are Alternatives to (Interchangeable with) the following series

| China GB | Z1, Z2, Z3, Z4, Z5, Z6, Z7A, Z7B, Z7C, Z8, Z9, Z10, Z11, Z12A, Z12B, Z12C, Z13, Z14, Z15, Z16, Z17A, Z17B, Z18, Z19A, Z19B, Z20, Z21, Z22 etc. |

| RINGFEDER | RfN 7003, RfN 7004, RfN 7005, RfN 7006, RfN 7007, RfN 7012, RfN 7012.2, RfN 7013.0, RfN 7014, RfN 7015.0, RfN 7015.1, RfN 7061, RfN 7110, RfN 7515, etc. |

| TSUBAKI | KE Series, AS Series, AD-N Series, AE Series, TF Series, RE Series, SL Series, EL Series, EF Series, etc. |

| CHIARAVALLI | RCK11, RCK13, RCK15, RCK16, RCK19, RCK40, RCK45, RCK50, RCK55, RCK70, RCK71, RCK80, RCK95, etc. |

| Rexnord Tollok | TLK110, TLK130, TLK131, TLK132, TLK133, TLK139, TLK200, TLK250, TLK250L, TLK300, TLK400, TLK401, TLK450, TLK451, TLK452, TLK500, TLK601, TLK602, TLK603, etc. |

| RINGSPANN | RLK608, RLK608E, RLK606, RLK603, RLK603 K, RLK603 S, RLK110, RLK110 K, RLK130, RLK131, RLK132, RLK133, RLK402, RLK404, RLK300, RLK200, RLK350, etc. |

| BIKON | 1003, 1006,1012, 4000, 5000, 7000A, 7000B, 8000, etc. |

| BONFIX | CCE1000, CCE2000, CCE3000, CCE4000, CCE4100, CCE4500, CCE4600, CCE4900, CCE8000, CCE9500, etc. |

| SATI | KLGG, KLCC, KLNN, KLDA, KLAA, KLDB, KLAB, KLPP, KLBB, KLHH, KLEE, KLFF, KLMM, etc. |

| COMPOMAC | A, B, C, D, ES/DS, EP, SD, F, etc. |

| VBLOK | VK400, VK800B, VK700, VK160, VK700.1, VK130, VK112, etc. |

| RINGBLOK | 1060, 1100, 1120, 1710, 1720, 1800, etc. |

| KANA | 200, 201, 300, etc. |

| KTR | KTR100, KTR150, KTR200, KTR201, KTR203, KTR206, KTR225, KTR250, KTR400, KTR603, etc. |

Apart from standard series, we can also design and produce tailored non-standard locking assemblies as per customers' specific requirements.

Incoporated in 1999, HOLK Bearing leads the way in the design and manufacture of quality Bearing Housings and Bearing Adapter Sleeves/Withdrawal Sleeves, we pride ourselves on an immediate and dedicated response to standard and special bearing housing solutions.

HOLK's max bearing housing fabrication capability: up to 5 tons/pc

We produce top-notch quality Split Plummer Blocks worth more than US$1,000,000 to a big famous European bearing company every year.

We manufacture premium quality Bearing Adapter Sleeves worth more than US$500,000 to a big famous European bearing company every year.

Category: Keyless Shaft Locking Assemblies