| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF,FCA,EXW |

| Payment Terms: | T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

| Means of Transport: | Ocean, Land |

| Production Capacity: | 1000 pcs/month |

| Packing: | Neutral Carton... |

| Delivery Date: | 30 days | Brand Name: | HOLK |

|---|---|---|---|

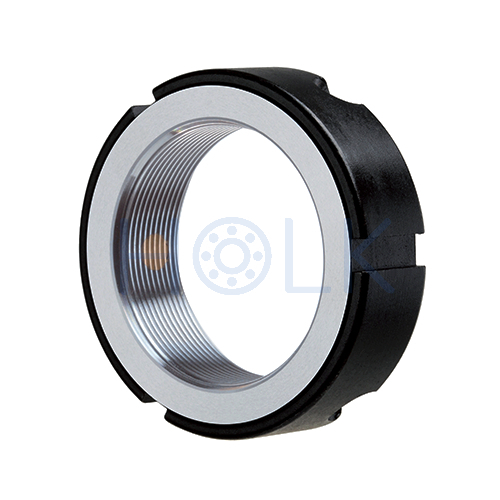

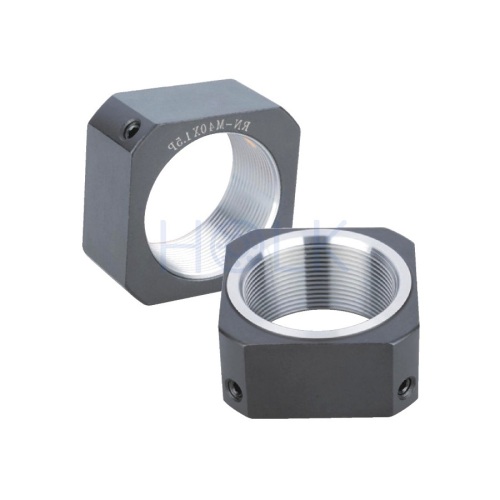

| Product Name: | Precision Lock Nuts | Series: | KMT Series |

| Model Numbers: | KMT 10, KMT 19, KMT 20 etc. | Material: | 42CrMo |

| Hardness: | HRC 28-32 | Lateral Deflection: | 0.002mm |

| Thread Tolerance: | Metric Thread ISO 4H | Features: | High Precision |

| Packaging: | Neutral Carton Box | Applications: | lathes, grinders, milling machines, motors, shut-off valves, spindle and ball screws |

KMT and KMTA Precision Lock Nuts are used to locate bearings in machines and equipment that require high precision such as lathes, grinders, milling machines, motors, shut-off valves, spindle and ball screws.

These nuts have 3 brass pins angularly distributed around its circumference which are tightened against the shaft by screws. The pins are machined to match the shaft thread and its tilt is equal to nut thread angle so the nuts are not subject to axial loads or deformation, allowing locking in the exact position. Although they use the same locking system, the KMT and KMTA nuts differ by the external profile and tightening tools required.

Precision lock nuts are made of Carbon steel as standard with optional choice of Stainless Steel.

Assembling

The KMT nuts are usually mounted with hook spanners, however, sizes up KMT 15 can be mounted using wrenches. The KMTA are mounted using pin wrenches or a pin-type face spanner and both of them are equipped with through-body screws. Once assembled, the bolts should be tighten lightly until each brass pin touches the shaft thread and only then tighten the screws alternately with a torque wrench until the recommended torque value is achieved for all the three bolts.

Removal

When removing the precision nuts KMT and KMTA, first loosen the three screws. Note that the brass pins can still be attached to the shaft thread, in order to proceed, tap the nuts near the pins using a copper or rubber hammer to loosen them. Only then remove the nut.

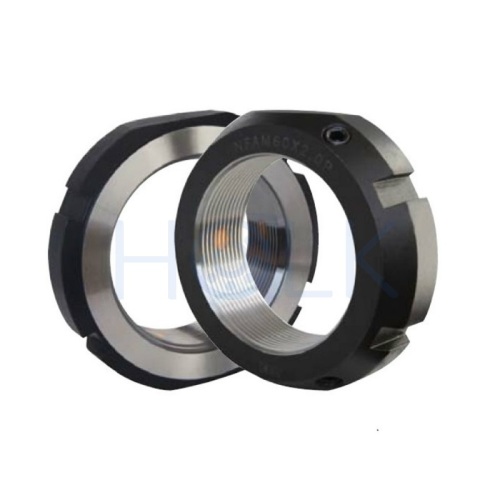

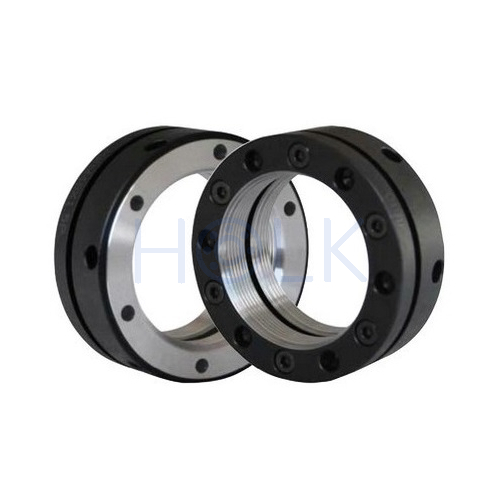

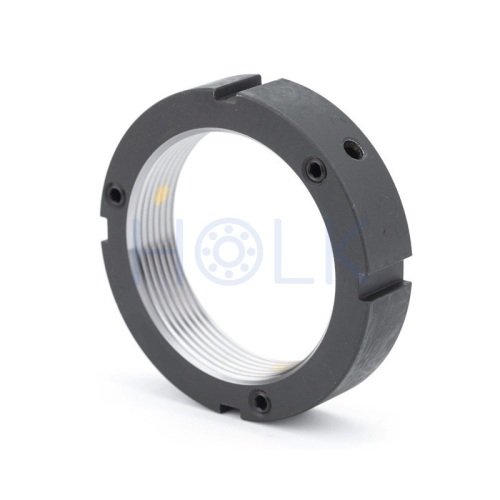

Image gallery of KMT series Precision Lock Nuts

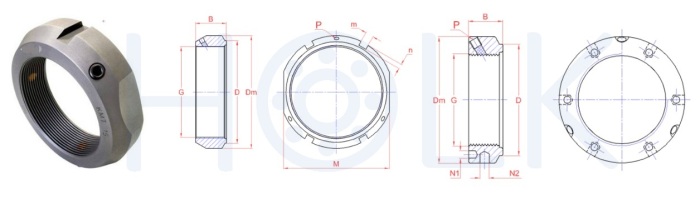

Drawing and Technical Data Sheet of KMT series Precision Lock Nuts

| Precision Nuts No. | G | Dm | D | B | m | n | M | N1 | N2 | P | Nm |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | |||

| KMT 0 | M 10x0.75 | 28 | 23 | 14 | 4 | 2 | 24 | M 5 | 4.5 | ||

| KMT 1 | M 12x1 | 30 | 25 | 14 | 4 | 2 | 27 | M 5 | 4.5 | ||

| KMT 2 | M 15x1 | 33 | 28 | 16 | 4 | 2 | 30 | M 5 | 4.5 | ||

| KMT 3 | M 17x1 | 37 | 33 | 18 | 5 | 2 | 34 | M 6 | 8 | ||

| KMT 4 | M 20x1 | 40 | 35 | 18 | 5 | 2 | 36 | M 6 | 8 | ||

| KMT 5 | M 25x1.5 | 44 | 39 | 20 | 5 | 2 | 41 | M 6 | 8 | ||

| KMT 6 | M 30x1.5 | 49 | 44 | 20 | 5 | 2 | 46 | M 6 | 8 | ||

| KMT 7 | M 35x1.5 | 54 | 49 | 22 | 5 | 2 | 50 | M 6 | 8 | ||

| KMT 8 | M 40x1.5 | 65 | 59 | 22 | 6 | 2.5 | 60 | M 6 | 8 | ||

| KMT 9 | M 45x1.5 | 70 | 64 | 22 | 6 | 2.5 | 65 | M 6 | 8 | ||

| KMT 10 | M 50x1.5 | 75 | 68 | 25 | 7 | 3 | 70 | M 6 | 8 | ||

| KMT 11 | M 55x2 | 85 | 78 | 25 | 7 | 3 | 80 | M 8 | 18 | ||

| KMT 12 | M 60x2 | 90 | 82 | 26 | 8 | 3.5 | 85 | M 8 | 18 | ||

| KMT 13 | M 65x2 | 95 | 87 | 28 | 8 | 3.5 | 90 | M 8 | 18 | ||

| KMT 14 | M 70x2 | 100 | 92 | 28 | 8 | 3.5 | 95 | M 8 | 18 | ||

| KMT 15 | M 75x2 | 105 | 97 | 28 | 8 | 3.5 | 100 | M 8 | 18 | ||

| KMT 16 | M 80x2 | 110 | 100 | 32 | 8 | 3.5 | M 8 | 18 | |||

| KMT 17 | M 85x2 | 120 | 110 | 32 | 10 | 4 | M 10 | 35 | |||

| KMT 18 | M 90x2 | 125 | 115 | 32 | 10 | 4 | M 10 | 35 | |||

| KMT 19 | M 95x2 | 130 | 120 | 32 | 10 | 4 | M 10 | 35 | |||

| KMT 20 | M 100x2 | 135 | 125 | 32 | 10 | 4 | M 10 | 35 | |||

| KMT 22 | M 110x2 | 145 | 134 | 32 | 10 | 4 | M 10 | 35 | |||

| KMT 24 | M 120x2 | 155 | 144 | 32 | 10 | 4 | M 10 | 35 | |||

| KMT 26 | M 130x2 | 165 | 154 | 32 | 12 | 5 | M 10 | 35 | |||

| KMT 28 | M 140x2 | 175 | 164 | 32 | 14 | 6 | M 10 | 35 | |||

| KMT 30 | M 150x2 | 185 | 174 | 32 | 14 | 6 | M 10 | 35 | |||

| KMT 32 | M 160x3 | 195 | 184 | 32 | 14 | 6 | M 10 | 35 | |||

| KMT 34 | M 170x3 | 205 | 194 | 32 | 14 | 6 | M 10 | 35 | |||

| KMT 36 | M 180x3 | 215 | 204 | 32 | 16 | 7 | M 10 | 35 | |||

| KMT 38 | M 190x3 | 225 | 214 | 32 | 16 | 7 | M 10 | 35 | |||

| KMT 40 | M 200x3 | 235 | 224 | 32 | 18 | 8 | M 10 | 35 | |||

| KMT 44 | Tr 220x4 | 265 | 254 | 36 | 20 | 10 | M 10 | 35 | |||

| KMT 48 | Tr 240x4 | 290 | 279 | 38 | 20 | 10 | M 12 | 60 | |||

| KMT 52 | Tr 260x4 | 310 | 299 | 38 | 20 | 10 | M 12 | 60 | |||

| KMT 56 | Tr 280x4 | 330 | 319 | 40 | 24 | 12 | M 12 | 60 | |||

| KMT 60 | Tr 300x4 | 360 | 349 | 42 | 24 | 12 | M 12 | 60 | |||

| KMT 64 | Tr 320x5 | 390 | 379 | 45 | 24 | 12 | M 12 | 60 | |||

| KMT 68 | Tr 340x5 | 410 | 399 | 48 | 24 | 12 | M 12 | 60 |

Notes:

Non-Standard Precision Locknuts are available upon request.

The above data is for reference only, we may change the specs without prior notice.

1Nm = 10.2kgf.cm = 0.73lb.ft

Incoporated in 1999, HOLK Bearing leads the way in the design and manufacture of quality Bearing Housings, Split Plummer Blocks, Bearing Adapter Sleeves, Withdrawal Sleeves, Precision Lock Nuts, Locking Assemblies, Hydraulic Nuts, Bearings and accessories. We pride ourselves on an immediate and dedicated response to standard and special bearing housing solutions.

HOLK's maximum bearing housing fabrication capability: up to 5 tons/pc

We produce top-notch quality Split Plummer Blocks worth more than US$1,000,000 to a big famous European bearing company every year.

We manufacture premium quality Bearing Adapter Sleeves worth more than US$500,000 to a big famous European bearing company every year.

Category: Precision Lock Nuts