| Min. Order: | 10 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CIF,FCA,EXW |

| Payment Terms: | T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

| Means of Transport: | Ocean, Land |

| Production Capacity: | 10000 pcs/month |

| Packing: | Neutral Carton... |

| Delivery Date: | 30 days | Brand Name: | HOLK |

|---|---|---|---|

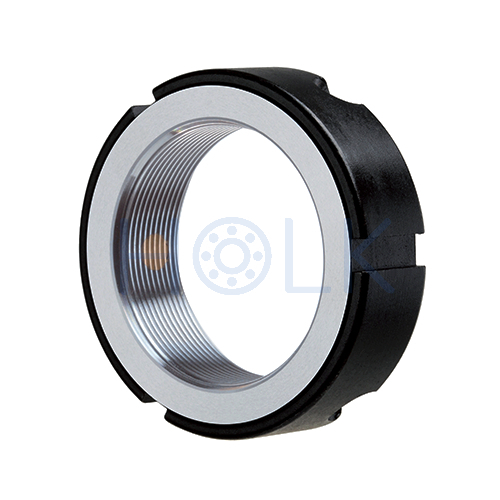

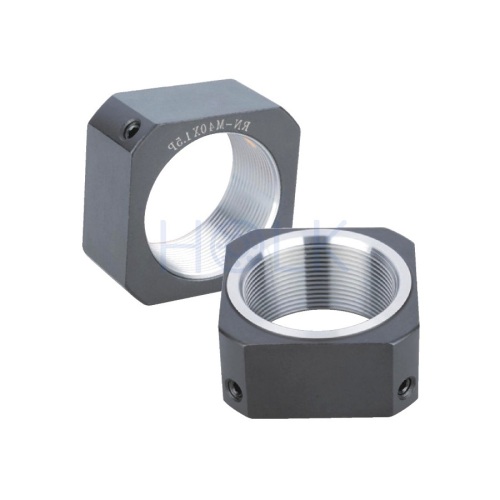

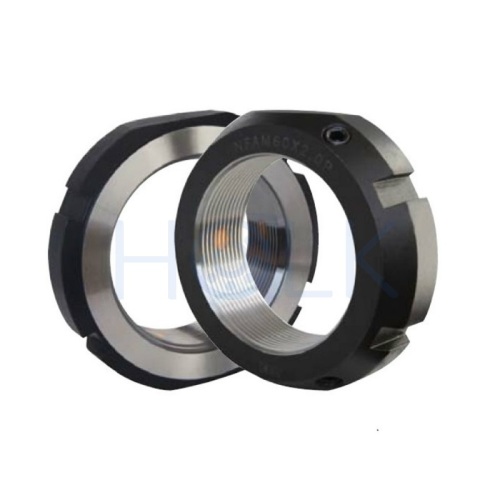

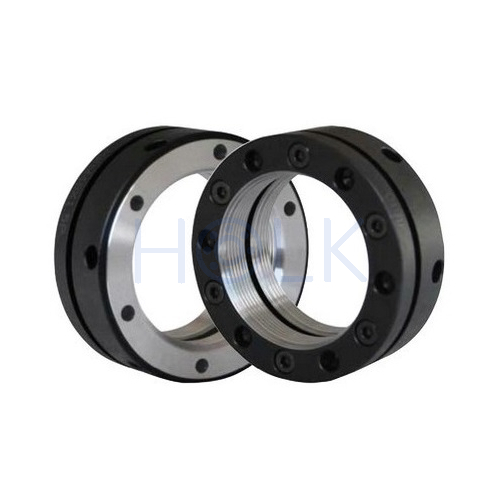

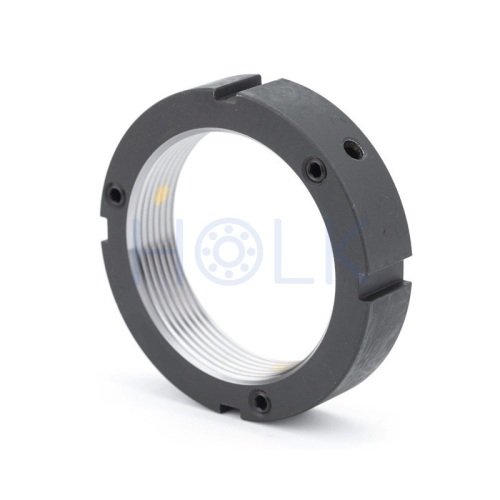

| Product Name: | Precision Lock Nuts | Series: | KMR Series, KM/R Series |

| Material: | 42CrMo | Hardness: | HRC 28-32 |

| Lateral Deflection: | 0.002mm - 0.005mm | Thread Tolerance: | Metric Thread ISO 4H |

| Features: | 3-way Radial Locking | Surface Treatment: | Alkaline Oxidation (Phosphatizing) |

| Manufacturing Method: | High Precision Turning and Grinding | Applications: | lathes, grinders, milling machines, motors, shut-off valves, spindle and ball screws |

The important accuracy requirements of a locknut bearing and the V-thread on a ballscrew or spindle are the fitness between the two and the squareness of the end where the locknut attaches the bearing. These factors directly affect the service life, reliability, and quality of the bearings and the ballscrews/spindles; this, of course, also has an effect on the image and quality of your products.

Our High Precision Lock Nuts are specially fabricated to meet your demanding requirements.

Technical Details

Product Name: High Precision Lock Nuts, Radial Locking Precision Lock Nuts

Series: KMR

Shape: Round

Material: 42CrMo

Hardness: HRC 28-32

Thread Accuracy: ISO 4H

Manufacturing Method: High Precision Turning and Grinding

Run Out: 0.002mm - 0.005mm

Applications: Ballscrews, High Precision Spindles, etc.

Features:

Our KMR series Precision Lock Nuts employ three-way raidial locking. The thickness is generally thinner than other series precision locknuts. This series locknuts are especially applicable for use when locknut space is limited. Apart from where other products are not usable because of space restrictions.

Drawing and Data Sheet of KMR series Precision Lock Nuts

| Model No./Thread | D | h | g | t | d | n-m | Max. Nm |

| KMR M6 x 0.5 | 16 | 8 | 3 | 2 | 13 | 2 - M4 | 3.5 |

| KMR M8 x 0.75 | 16 | 8 | 3 | 2 | 13 | 2 - M4 | 3.5 |

| KMR M10 x 0.75 | 18 | 8 | 3 | 2 | 16 | 2 - M4 | 3.5 |

| KMR M10 x 1.0 | 18 | 8 | 3 | 2 | 16 | 2 - M4 | 3.5 |

| KMR M12 x 1.0 | 22 (20) | 8 | 3 | 2 | 18 | 2 - M4 | 3.5 |

| KMR M12 x 1.25 | 22 (20) | 8 | 3 | 2 | 18 | 2 - M4 | 3.5 |

| KMR M14 x 1.5 | 25 | 8 | 3 | 2 | 21 | 2 - M4 | 3.5 |

| KMR M15 x 1.5 | 25 | 8 | 3 | 2 | 21 | 2 - M4 | 3.5 |

| KMR M16 x 1.5 | 28 | 10 | 4 | 2 | 23 | 2 - M5 | 4.5 |

| KMR M17 x 1.0 | 28 | 10 | 4 | 2 | 23 | 2 - M5 | 4.5 |

| KMR M18 x 1.5 | 30 | 10 | 4 | 2 | 25 | 2 - M5 | 4.5 |

| KMR M20 x 1.0 | 32 | 10 | 4 | 2 | 27 | 3 - M5 | 4.5 |

| KMR M20 x 1.5 | 32 | 10 | 4 | 2 | 27 | 3 - M5 | 4.5 |

| KMR M22 x 1.5 | 35 | 10 | 4 | 2 | 30 | 3 - M5 | 4.5 |

| KMR M24 x 1.5 | 38 | 12 | 5 | 2 | 33 | 3 - M6 | 8 |

| KMR M25 x 1.5 | 38 | 12 | 5 | 2 | 33 | 3 - M6 | 8 |

| KMR M27 x 1.5 | 42 | 12 | 5 | 2 | 37 | 3 - M6 | 8 |

| KMR M30 x 1.0 | 45 | 12 | 5 | 2 | 40 | 3 - M6 | 8 |

| KMR M30 x 1.5 | 45 | 12 | 5 | 2 | 40 | 3 - M6 | 8 |

| KMR M33 x 1.5 | 52 | 12 | 5 | 2 | 45 | 3 - M6 | 8 |

| KMR M35 x 1.5 | 52 | 12 | 5 | 2 | 47 | 3 - M6 | 8 |

| KMR M36 x 1.5 | 55 | 14 | 6 | 2.5 | 49 | 3 - M6 | 8 |

| KMR M39 x 1.5 | 58 | 14 | 6 | 2.5 | 52 | 3 - M6 | 8 |

| KMR M40 x 1.5 | 58 | 14 | 6 | 2.5 | 52 | 3 - M6 | 8 |

| KMR M42 x 1.5 | 62 | 14 | 6 | 2.5 | 56 | 3 - M6 | 8 |

| KMR M45 x 1.5 | 65 | 14 | 6 | 2.5 | 59 | 3 - M6 | 8 |

| KMR M48 x 1.5 | 68 | 14 | 6 | 2.5 | 62 | 3 - M6 | 8 |

| KMR M50 x 1.5 | 70 | 14 | 6 | 2.5 | 64 | 3 - M6 | 8 |

| KMR M52 x 1.5 | 73 | 16 | 8 | 3 | 66 | 3 - M8 | 18 |

| KMR M55 x 2.0 | 75 | 16 | 8 | 3 | 68 | 3 - M8 | 18 |

| KMR M56 x 2.0 | 77 | 16 | 8 | 3 | 70 | 3 - M8 | 18 |

| KMR M60 x 1.5 | 80 | 16 | 8 | 3 | 73 | 3 - M8 | 18 |

| KMR M60 x 2.0 | 80 | 16 | 8 | 3 | 73 | 3 - M8 | 18 |

| KMR M64 x 2.0 | 85 | 16 | 8 | 3 | 78 | 3 - M8 | 18 |

| KMR M65 x 2.0 | 85 | 16 | 8 | 3 | 78 | 3 - M8 | 18 |

| KMR M68 x 2.0 | 92 | 18 | 8 | 3.5 | 84 | 3 - M8 | 18 |

| KMR M70 x 2.0 | 92 | 18 | 8 | 3.5 | 84 | 3 - M8 | 18 |

| KMR M72 x 2.0 | 95 | 18 | 8 | 3.5 | 86 | 3 - M8 | 18 |

| KMR M75 x 2.0 | 98 | 18 | 8 | 3.5 | 90 | 3 - M8 | 18 |

| KMR M76 x 2.0 | 100 | 18 | 8 | 3.5 | 92 | 3 - M8 | 18 |

| KMR M80 x 2.0 | 105 | 18 | 8 | 3.5 | 96 | 3 - M8 | 18 |

| KMR M85 x 2.0 | 110 | 18 | 8 | 3.5 | 102 | 3 - M8 | 18 |

| KMR M90 x 2.0 | 120 | 20 | 10 | 4 | 108 | 3 - M8 | 18 |

| KMR M95 x 2.0 | 125 | 20 | 10 | 4 | 113 | 3 - M8 | 18 |

| KMR M100 x 2.0 | 130 | 20 | 10 | 4 | 118 | 3 - M8 | 18 |

| KMR M105 x 2.0 | 140 | 22 | 12 | 5 | 125 | 3 - M10 | 18 |

| KMR M110 x 2.0 | 145 | 22 | 12 | 5 | 132 | 3 - M10 | 18 |

| KMR M115 x 2.0 | 150 | 22 | 12 | 5 | 137 | 3 - M10 | 18 |

| KMR M120 x 2.0 | 155 | 24 | 12 | 5 | 142 | 3 - M10 | 18 |

| KMR M125 x 2.0 | 160 | 24 | 12 | 5 | 147 | 3 - M10 | 18 |

| KMR M130 x 2.0 | 165 | 24 | 12 | 5 | 152 | 3 - M10 | 18 |

| KMR M135 x 2.0 | 175 | 26 | 14 | 6 | 160 | 3 - M10 | 35 |

| KMR M140 x 2.0 | 178 | 26 | 14 | 6 | 165 | 3 - M12 | 35 |

| KMR M145 x 2.0 | 190 | 26 | 14 | 6 | 175 | 3 - M12 | 35 |

| KMR M150 x 2.0 | 195 | 26 | 14 | 6 | 180 | 3 - M12 | 35 |

| KMR M155 x 3.0 | 200 | 28 | 16 | 7 | 180 | 3 - M12 | 35 |

| KMR M160 x 3.0 | 210 | 28 | 16 | 7 | 190 | 3 - M12 | 35 |

| KMR M165 x 3.0 | 210 | 28 | 16 | 7 | 190 | 3 - M12 | 35 |

| KMR M170 x 3.0 | 220 | 28 | 16 | 7 | 200 | 3 - M12 | 35 |

| KMR M180 x 3.0 | 230 | 30 | 18 | 8 | 205 | 3 - M12 | 60 |

| KMR M190 x 3.0 | 240 | 30 | 18 | 8 | 215 | 3 - M12 | 60 |

| KMR M200 x 3.0 | 250 | 32 | 18 | 8 | 225 | 3 - M12 | 60 |

| KMR M210 x 4.0 | 270 | 34 | 18 | 8 | 238 | 3 - M12 | 85 |

| KMR M220 x 3.0 | 270 | 34 | 18 | 8 | 245 | 3 - M12 | 85 |

| KMR M220 x 4.0 | 270 | 34 | 18 | 8 | 245 | 3 - M12 | 85 |

| KMR M240 x 4.0 | 290 | 34 | 18 | 8 | 265 | 3 - M12 | 85 |

| KMR M260 x 3.0 | 310 | 36 | 18 | 8 | 285 | 3 - M12 | 85 |

| KMR M260 x 4.0 | 310 | 36 | 18 | 8 | 285 | 3 - M12 | 85 |

| KMR M280 x 4.0 | 330 | 36 | 18 | 8 | 305 | 3 - M12 | 85 |

| KMR M300 x 4.0 | 350 | 36 | 18 | 8 | 325 | 3 - M12 | 85 |

Notes:

Non-Standard Precision Locknuts are available upon request.

The above data is for reference only, we may change the specifications without prior notice.

1Nm = 10.2kgf.cm = 0.73lb.ft

Incoporated in 1999, HOLK Bearing leads the way in the design and manufacture of quality Bearing Housings, Split Plummer Blocks, Bearing Adapter Sleeves, Withdrawal Sleeves, Precision Lock Nuts, Locking Assemblies, Hydraulic Nuts, Bearings and accessories. We pride ourselves on an immediate and dedicated response to standard and special bearing housing solutions.

HOLK's maximum bearing housing fabrication capability: up to 5 tons/pc

We produce top-notch quality Split Plummer Blocks worth more than US$1,000,000 to a big famous European bearing company every year.

We manufacture premium quality Bearing Adapter Sleeves worth more than US$500,000 to a big famous European bearing company every year.

Category: Precision Lock Nuts